Find the programme that meets your requirements and aspirations.

Apply nowStudent Blogs

- SPJIMR

- Blog

- Green supply chains: Accelerating decarbonization through data & digital tech

Green supply chains: Accelerating decarbonization through data & digital tech

Theme- The Supply Chain Reinvention: Embracing Digitalization and Decarbonization

Article Submission for Catena Aurea, NMIMS Mumbai.

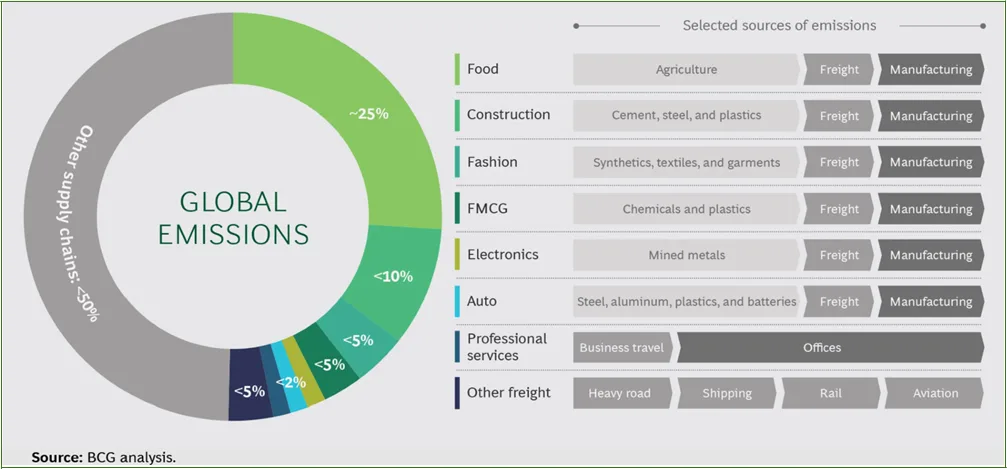

Supply chains are the nervous system of the business world, responding to stimuli and generating relevant responses to keep the cogs of organizations running. But in doing so, they generate some unwanted results which are wasteful for all stakeholders involved, including the environment. A McKinsey report proves that the adverse effects of supply chains are responsible for more than 80% of greenhouse gas emissions, with 90% of that impact on air, land, water, biodiversity and geological resources [1]. Just 8 different industry supply chains globally contribute more than 50% of annual greenhouse gas emissions, says a BCG study [2]. Manufacturing makes a small portion of this, with most of it dominated by agriculture, procurement of raw materials, and freight transport. It is important to realize that the business of business is no longer just business. In their chase of profit, organizations have a responsibility towards people and the planet too. Hence, sustainability in supply chains, which underpins a company’s triple bottom-line goals, is the need of the hour. Businesses must incorporate green supply chains to reduce their carbon footprint, and data and technology can help accelerate this objective. Read on to know more!

A green supply chain is an approach to reduce the environmental impact of a supply chain along the product/service lifecycle [2]. To achieve sustainable development, supply chains need to not only focus on transport or logistical activities, but also on the conservation of mass and energy throughout the chain. Green supply chains must be built around 3 pillars of sustainability recognized by the Environmental Protection Agency (EPA) [3]- environmental, social and economic pillars. While it makes intuitive sense for green supply chains to focus heavily on environmental benefits, one can’t ignore the social pillar of protecting marginalized communities, and the economic pillar of safeguarding people’s livelihoods, without compromising on the goal of reducing the harmful emissions to the planet. Incorporating sustainability and decarbonizing supply chains leads to the following benefits [4] for firms:

- Cost Reduction: Investing in making supply chains green reduces costs in the long run for organizations, by implementing IT solutions that consume less energy, give accurate predictions, and replace/recycle existing energy sources. Nike’s sustainable initiatives in its supply chain reduced 50% of its labor costs and 20% of its material usage, to achieve 0.25% higher margins [4].

- Risk Reduction: Digital security solutions deployed in green supply chains ensure transparency, safety and authenticity in business operations. With green digital solutions, businesses can avoid unethical practices and partners, and track every single piece of physical or digital information across the green supply chains.

- Compliance: Government regulations are ensuring that businesses comply with green supply chain initiatives. This helps firms get certified and recognized by world bodies as pioneers of sustainability. 6% of leading companies around the world are taking action by removing suppliers who can’t manage carbon footprint, with this number expected to rise to 56% in the future [4].

- Resource Utilization: If a company decides to incorporate green supply chains, it would result in more targeted (and hence lesser) utilization of resources. This will allow companies to be agile and lean across their value chain, and produce/re-cycle at the same rate as the consumption of their offering.

- Competitive Advantage: By going green in supply chains, organizations automatically gain an edge over competition, fulfilling consumer expectations better. Studies show that customers are ready to spend more on products that follow green logistics practices and transparent supply chains. With decarbonized, green supply chains, businesses can build their brand reputation and sustain their brand image.

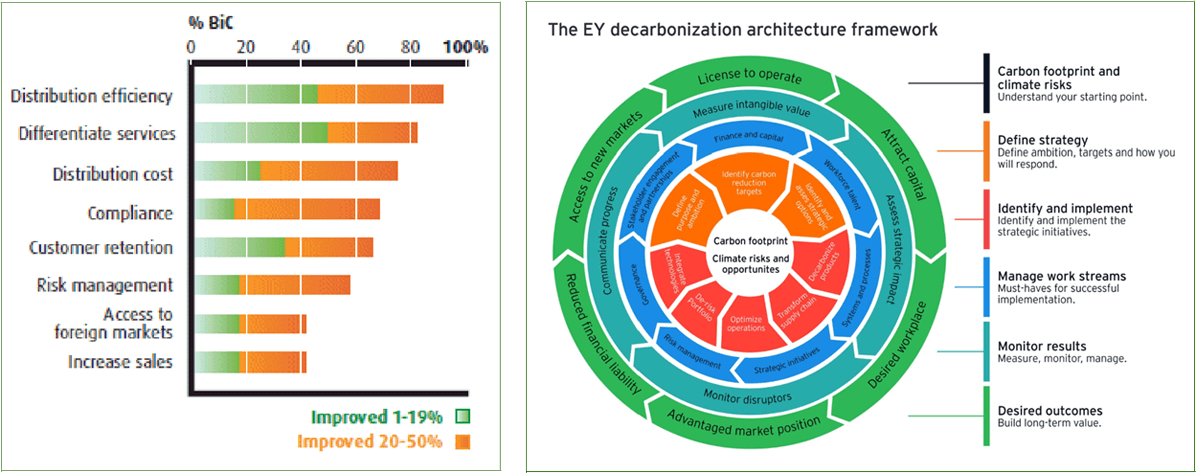

If done well, green supply chains can have several ways of business gain, beyond just environmental benefits. In a study conducted with logistics and transportation service providers from Canada, several extra business benefits were highlighted which were best-in-class (BiC), leading to customer retention, access to newer markets and an increase in revenue [5].

So how can supply chains be made green in companies which have been operating with traditional networks for legacy years? A framework by EY lays down the path for firms to build such green, decarbonized supply chains [6]. EY says that organizations must understand the relevant climate risks from their business, define a strategy to set targets for change, identify opportunity areas to intervene with green initiatives, and actively implement their strategic initiatives while managing work streams. Additionally, companies should keep monitoring results and changes from their initiatives and remodel the supply chain to align with set goals of sustainable impact. In my opinion, Unilever, the global FMCG giant, forms a great case study. The organization has understood how detrimental the operations of a CPG company are for the environment, so it has strategized to reduce scope 1 and scope 2 emissions by 100%, and halve the full value chain emissions of their products by 2030 [7]. It has already deployed blockchain technology to ensure responsible sourcing of palm oil used in its products [8], while its Dapada factory in India has become a part of the Global Lighthouse Network, recognized by the World Economic Forum as a top site to use tech to innovate and practice sustainability [9]. WalMart follows a scheme called Packaging Scorecard for its suppliers, calculating the ‘green quotient’ of packaging [10], aligning with its larger goals of reducing packaging cost by 5% and stopping debris from reaching landfills. WalMart’s initiative is set to save 67 million gallons of diesel and 324K tons of coal annually. Ford has focused heavily on the use of recovered materials, with innovations around recycling and reuse helping the North American division of the company produce 95% of its vehicles from scrap metal. Ford claims to recover 86% of its vehicle by weight through recycling and remanufacturing [10]. FedEx has focused on reducing carbon emissions, by cutting fuel consumption in its fleets by 47% [10]. Other notable mentions include Toyota, GSK, Adobe, UPS and Johnson & Johnson which are recognized among the top green supply chains in the world [11]. These examples are proof enough for organizations to be inspired to incorporate green, decarbonized supplies more actively into their business.

So how can they do this? Technology and data come to the rescue here for companies. Let’s understand this through five different use cases [12].

- Companies like Evigence are using cold-chain solutions made with IoT (Internet of Things) that can track food temperature to help restaurants and retailers sell food at the opportune time and avoid waste.

- The company RigiTech developed an autonomous drone for rapid cargo delivery that reduced CO2 emissions by half, and delivery times plus transport costs by 10 times.

- TextileGenesis has developed a blockchain platform for fashion brands, verifying the origin of materials by using digital tokens as the supply chain “currency” end-to-end and deploying information transparently.

- For organizations who wish to begin understanding their carbon footprint and take that step of sustainability, AI and ML could be used as a carbon calculator. The organization Carbon Chain has developed such a calculator to give accurate carbon footprint information within 10 minutes.

- The organization Searoutes has reduced emissions by 60% through an AI-based ‘eco-calculator’ for freight transportation.

But green supply chains have their own challenges. It is difficult for organizations to disturb their existing legacy supply chains and make a sensible business case to superiors to allow investment into tech for green supply chains. Many companies abandon their efforts simply after calculating their carbon footprint, without taking any action. Suppliers are often non-compliant in terms of being a part of decarbonized chains. And in many cases, businesses don’t understand the extent of the opportunity loss with not having a green supply chain. In my opinion, following are some of the ways to overcome these obstacles:

- Share and receive data from suppliers and make a value chain emissions baseline

- Set ambitious reduction targets for scopes 1-3 emissions and publicly declare progress

- Imbibe sustainability in design- recycling, greener materials & redesign existing products

- Rethink make-or-buy decisions and need for long-range logistics..

- Incorporate metrics related to emission in standards of procurement

- Work in partnership with suppliers to educate and support them to address their emissions

- Push industry bodies for sector initiatives on sharing, certification, tracing and policies

- Go for joint commitments on green materials to encourage upstream investments

- Change internal operations like procurement, product development, and finance

- Ensure better governance for carbon reduction to align internal teams & empower firm

In the long run, green supply chains will be a prerequisite for businesses to be sustainable. Despite the challenges highlighted, there are mechanisms supported by data and digital technology that can accelerate the adoption and implementation of green supply chains. The world is moving towards a new era where businesses must play their part in safeguarding their future by protecting the future of the planet. To become truly sustainable, organizations must realize the dual-level benefits of a green supply chain for the firm and the environment. Supply chain decarbonization is a challenging yet fruitful opportunity for businesses to leverage technology to build green supply chains and activate international climate action.

[1] https://www.billerud.com/managed-packaging/knowledge-center/articles/supply-chain-carbon-footprint#:~:text=According%2 0to%20McKinsey%2C%20the%20typical,water%2C%20biodiversity%20and%20geological%20resources.

[2] https://www.bcg.com/publications/2021/fighting-climate-change-with-supply-chain-decarbonization

[3] https://www.sciencedirect.com/topics/engineering/green-supply-chain#:~:text=A%20green%20supply%20chain%20or,materia l%20to%20the%20end%20product.

[4] https://www.billerud.com/managed-packaging/knowledge-center/articles/supply-chain-carbon-footprint#:~:text=According%2 0to%20McKinsey%2C%20the%20typical,water%2C%20biodiversity%20and%20geological%20resources.

[5] https://www.trademo.com/blog/2020/12/29/what-is-green-supply-chain-and-its-benefits/

[6] https://ised-isde.canada.ca/site/logistics-canada/en/publications/green-supply-chain-management/logistics-and-transportation-s ervices/green-supply-chain-management-logistics-and-transportation-services-canadian-perspective-2#Figure_364_eng

[7] https://www.ey.com/en_gl/supply-chain/why-net-zero-supply-chains-are-the-next-big-opportunity-for-business

[8] https://www.unilever.com/planet-and-society/climate-action/strategy-and-goals/

[9] https://www.techtarget.com/searchsap/news/252515342/Unilever-pursues-supply-chain-sustainability-with-blockchain

[10] https://www.livemint.com/companies/hindustan-unilever-s-dapada-factory-becomes-part-of-lighthouse-network-1164864589 6532.html

[11] https://www.mbaskool.com/business-articles/operations/16360-green-supply-chain-examples-of-companies.html

[12] https://supplychaindigital.com/top10/top-10-green-supply-chains

[13] https://www.softeq.com/blog/green-supply-chain-management-use-cases-and-benefits

No Plagiarism Proof (screenshots from online tools)

Recent Posts

- #DoCCDiaries: Community springs in the Bag Guler Panchayat July 9, 2024

- Experiential learning: My month-long advocacy internship with PGDM’s DoCC June 25, 2024

- My journey: Transforming lives through Abhyudaya June 6, 2024

- Discovering cutting-edge applications of AI and ML in the finance sector June 4, 2024

- #DoCCDiaries: Durbar: Fight against stigma for ‘dignity of profession’ May 28, 2024